Waxcloth? Tin Cloth?

So, besides my other hobby interests I am actually an avid camper. That is, I aspire to be when I have the time to get out. I have been busy as of late with recent additions to the family and a pandemic dissuading a lot of trips away from home in general, although I think camping is one of the more safer activities one can do despite the viral concerns on earth. Anyway.

I have been reading a lot about bushcraft and been practicing tying knots and reorganizing my camping supplies and cutting down on needless redundancies while getting a few other various bits of gear and just doing all the ‘pre-camping’ stuff despite not having a trip planned anytime soon.

I came across the concept of waxcloth, AKA tincloth, as a way to waterproof and toughen up clothing for inclement weather in the ‘olden days’ so to speak. Mostly for tarps and stuff, but also used on jackets, pants, gloves, etc. I was intrigued by the concept and began to graduate my study from the book to youtube and imagine all the bearded fellows I found. It was a great many.

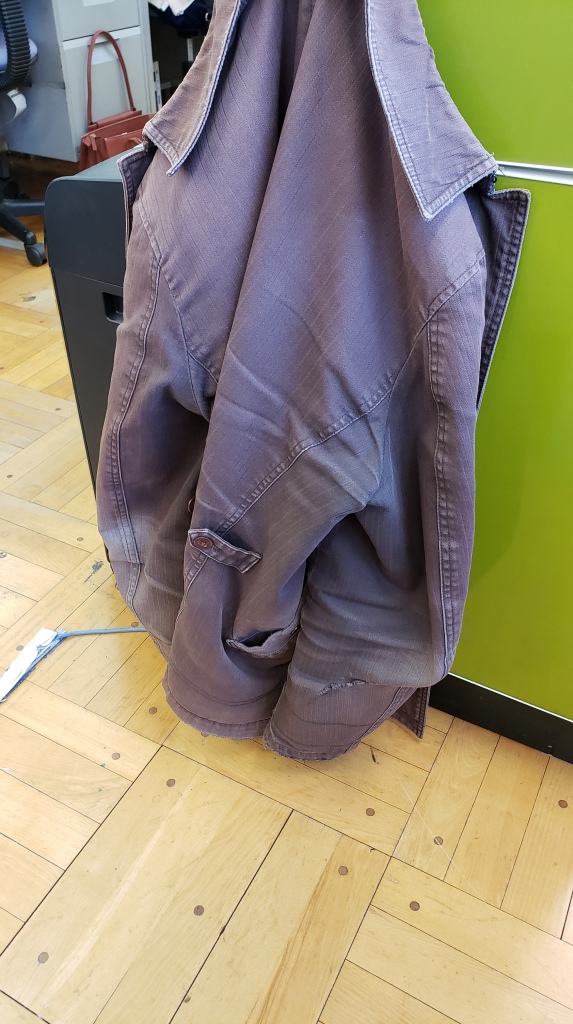

So I have an old jacket which I really like, but its beat up, torn in a bunch of places, and missing buttons too.

I love this jacket. But since it is so old and cruddy (Although beloved) I figured that it would be a good guinea pig for this process which appears quite simple, but also might render the jacket not really wearable in certain contexts. But from what I saw online it would toughen the fabric, make it fairly waterproof, and also prevent wear and tear. I figured why not, and if it became my ‘adventure jacket’ and I couldn’t wear it in public without looking ridiculous, so be it.

Cloth wax is hella expensive.

Maybe not ALL cloth wax, but most of it is pretty pricey and you get so little for what you are paying. The internet is on its hands and knees for otter wax and they seem to have the ‘high end clothing wax’ market cornered. I wonder who tricked the rich into throwing their money at them so seriously. I don’t have the time or interest to find out. They want like 40+ dollars for a bar of wax that is only about 65 grams. I mean, they want 100 dollars for a damn wooden stick to apply the wax. They got these fools begging on hands and knees for it. I don’t have 50 bucks for a tiny bar of wax.

Of course, amazon is there in the clutch to suggest to me cheap alternatives. THe Greenland Wax by Fjall Raven appears to be the same thing generally and you only have to pay about 16 bucks for 100 grams of it. Not terrible when your alternative is selling your soul for barely a palmful of otter’s blessing. Get real.

My research continued and while greenland wax was an option, I still figured I’d need more wax that that for my jacket and while 30 bucks isn’t horrendous for 200g of specially made cloth wax built for the job, everyone online was making their own for next to nothing.

While doing a bit of shopping with the family, we went to the hobby super center which has some of the more obscure hobbies covered, in this case candlemaking, and picked up some wax. Almost all recipes call for a 1 to 1 mix of parafin wax and beeswax. 1KG of parafin was about 6 bucks and 500 G (1/2 a KG) of beeswax was about 15 dollars. 21 bucks for 1500 G of wax. Now scroll back up and see how much otter wax is charging for 60 grams. God they really know what they are doing. Good on them, but damn I will not be fooled to that extent. Also, raw beeswax pellets smell really nice. I hope my jacket smells that nice too, but not so nice it attracts creatures to consume me.

Anyway, onto the project in earnest – making cloth wax.

Making cloth wax pucks.

So I didn’t want to use it all , but figured more then 100 grams would be needed so I settled on a mix of 150g of bees to 150g of parafin using an electric scale. And I put it in a spare jar I had since I didn’t want to wax up my pan since I use it for cooking and cleaning wax in great amounts of a tremendous pain in the ass. Most online dudes just melted it straight in a pot of some kind, but I wasn’t in a position to do that and improvised.

So I set up my double boiler system by putting the jar in a pot of boiling water, preserving the pan for regular use and still getting the job done, albeit a little slower than I could have. It did the job no problem at all.

I used a kebab skewer to stir it, but could have used a chop stick or whatever else on hand. Just wanted to avoid using things I eat with regularly to save me clean up later.

It all melted down nicely and mixed well. Smelled great too. This is also the first time that I am using my new leather gloves! I used cheap gloves when doing more heavy duty camp stuff, but it was time and as I mentioned before, I was in a ‘pre-camp’ prep fever and this was one of the purchases made. Only 5 bucks! not bad. But that way I could pour the wax from the jar with more confidence than using pot holders or a damp towel.

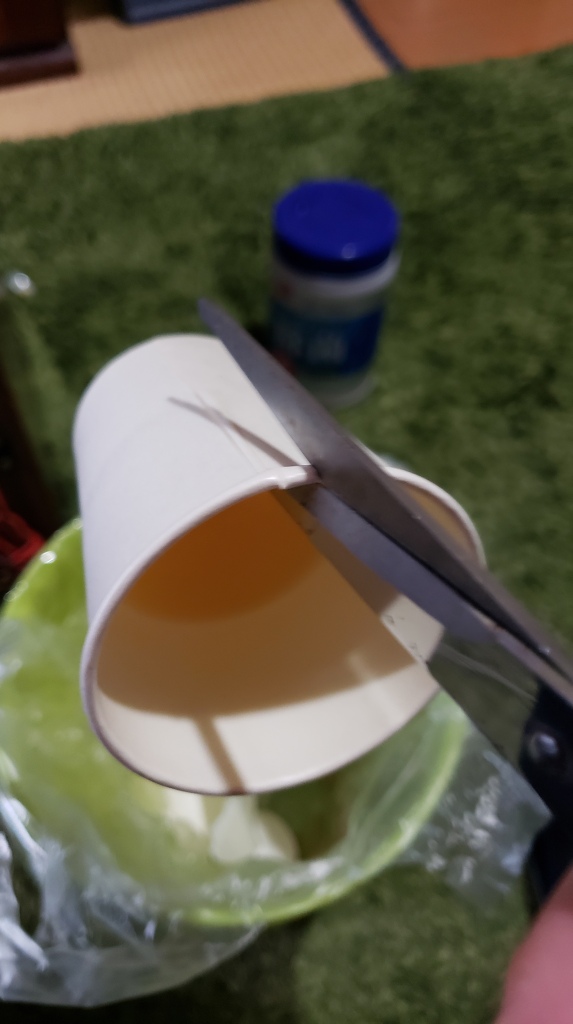

How does one make pucks of wax? Most dudes online used paper or plastic cups and I had a bunch of these little medium sized dixie cups which were perfect. I even put down a paper towel like an adult in case I spilled. I didn’t. The 300g of cloth wax ended up filled about 5 cups close to halfway which essentially makes 5 60 gram pucks for my personal use. Something that the Otter wax company would charge close to 200 dollars for, and greenland wax almost 50. Nobody is knocking them, but just pointing out the reality of what I am seeing here. I spent 20 and could make 15~20 pucks no problem and only need to get more beeswax when I run out of that. I digress. (I also am saving some serious money!)

After a little while in my cold af house they cooled off enough that they sounded hard when tapped upon. So I sat down, cut along the natural seam of the cup and then pulled it off. Besides the bottoms of the cups, they came off very easily and the shape was perfect as well. At this stage I knew that I was in luck and had a potential serious success on my hands.

So besides the bottom bit, it came off clean. Look at how nicely it hardened and dried. I am slowly getting interested in pouring resin and this actually made me quite interested to keep up with preparing and studying for that endeavor. I had no trouble pulling the bottom part of the cup off when I took little tugs at it going in a circle and it came off easy.

So I left a few cup bottoms on figuring it might be a nice base to hold onto or something. Maybe if I get the wax down to the bitter end having it attached to something will allow me to get those last extra grams out of it. Otherwise I will toss it back into the wax bag to melt again. Or perhaps just eat it. Yeah I ate some. Deal with it.

So the puck making process was a great success. Great value, and all in all only took about an hour not counting cooling time. I needed to be by the stove and stirring which sped that process up, but otherwise it could be done at a very very leisurely pace in my opinion.

The next phase will be waxing up the jacket, and exposing it to heat to seal it and combine the wax and cloth together to form what will become I am hoping my brand new jacket and an heirloom for times to come. I have read lots of good things and watched videos of people expressing the same as well. I am looking forward to it.

I actually managed to get a camping trip sorted out and because I am a magician with great ties to the element of fire, want to make sure that I am not using a hair dryer or press on iron or anything and that I am using proper camp fire to hopefully seal in some camp fire juices and smokey flavor into this jacket as well. That is actually in a week or two from posting this and I am very excited to see how she goes.

We shall see in the latter half of this post on making a tincloth jacket from scratch. Although the jacket is not made from scratch, I am making the wax and going through the process by scratch for the most part so don’t bother me with semantics.

Until we meet again!

tRM!

Leave a comment